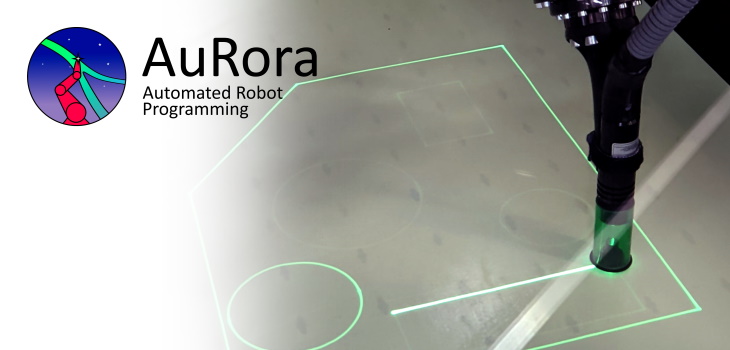

Validation research for the automated generation of optimal, collision-free robot movements in existing offline simulation environments

Offline programming

Anyone who automates with industrial robots will know the advantages of offline programming environments (OLP) and use them for themselves. Many plant operators, plant builders and system integrators prepare their robot programs within these environments, for example to shorten the downtime of production lines in case of adjustments, to check the feasibility of the application or to estimate the cycle time. Process-dependent effective movements can be generated fairly quick today. The processes are known and the experience of the process technicians provides the necessary parameters.

Time wasters in offline programming

But can the process paths with this tool in this configuration be run completely without triggering a programme abort in the robot controller? Is there even a configuration that can do this? Can the robot switch between several sub-processes without collision? Is a configuration change necessary for this change? What is the fastest sequence of all subprocesses? Does the robot collide with itself or the environment between the programmed support points?

Offline simulation of the robot program

A robot programmer solves these and other challenges. He simulates his solution approach within his OLP software. If the simulation aborts with an error message, he reacts by adapting it and tests the programme again until the next error message. Depending on the task, this iterative workflow takes a lot of time and also depends on the skills of the robot programmer. If a change is made to the workpiece or a second variant of the system is to be evaluated, in the worst case a similar amount of work is required again. And there is always the possibility that there is an alternative solution with a faster cycle time.

What we improve

Our algorithms can automatically check within minutes whether solutions exist for the existing application simulation. If this is the case, the fastest solution found is imported into the OLP software via cycle time optimisation. The programmer can check and process this with his usual workflow.

We are currently evaluating our research on the user side within the OLP environments Artiminds RPS and KUKA.Sim 4.3 by providing the following approaches:

- Automatic path generation for collision-free infeed and support movements between effective movements

- Automatic correction of erroneous effective movements due to inappropriate robot configurations and orientations

- Cycle time reduction through optimal task sequencing and optimisation of the infeed movements based on our own RCS computing modules

More project details are available here.

What we are looking for

The field of robot manufacturers and users is diverse. For the evaluation of our algorithms, we are looking for partners who automate their production with industrial robots themselves or offer this as a service for other companies. Furthermore, we are interested in information or cooperations that can help us to find the mentioned application scenarios or companies.

In addition, the current progress of the project is focusing on utilisation scenarios. Our approaches are very promising and the demand is already there at this early stage. It is unlikely that this can be met elsewhere in the short term. Therefore, we are looking for partners and cooperations who want to use and further develop the existing innovations in this area with us.

We are currently in the second phase of the application process for the EXIST research transfer. If PtJülich recognizes the same potentials that we see in our results, VIP+ AuRora will be evolved to EXIST-FT funding from August 1st, 2023 and will be called EXIST AuRora.

Interest aroused? Write to us! Contact

Additional potential of our algorithms

In addition to the improvements mentioned above, the algorithms developed from our research also have the potential to provide answers to further user questions. In this respect, we are looking at the following areas in perspective

- Automatic robot selection for existing effective paths

- Automatic placement suggestions of robots in the simulation environment

- Automatic placement of effective paths in the robot's workspace

- Review and improvement of existing solutions

- Making CNC code runnable on industrial robots

- Extension of the automatic program planning to the an environment planning of the industrial robot